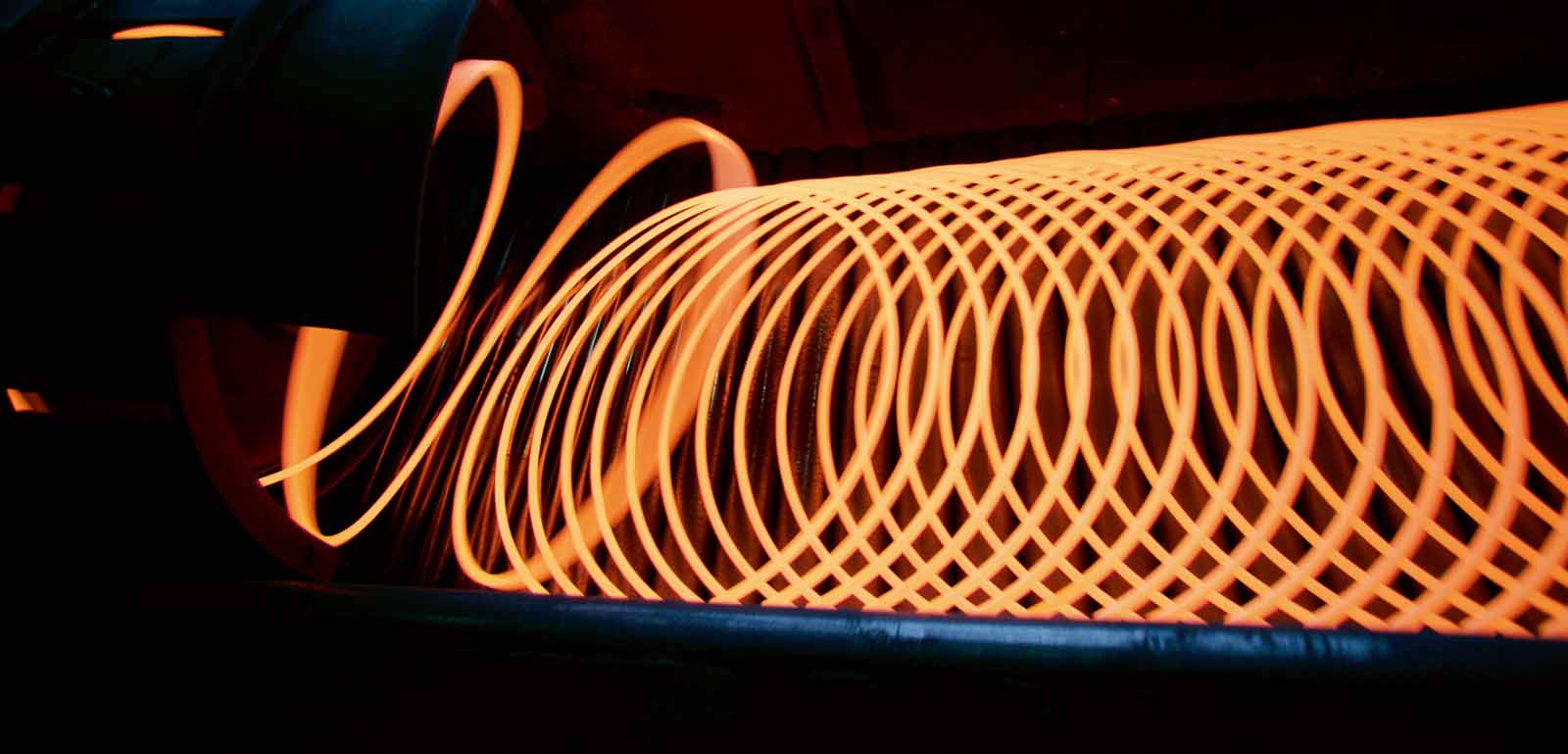

Steel is an important raw material for construction and is therefore in high demand. Energy consumption in conventional production is considerable, making this sector a major lever for achieving climate targets. A key element here is the conversion of production to electricity-powered arc furnaces. This means that scrap steel can be recycled to reproduce steel. This also means that scrap is now becoming a valuable resource worldwide.

Why we are addressing this topic:

- Decarbonization is taking place worldwide – meaning that fossil fuels are being replaced by more sustainable energy sources. It’s about creating a more climate-friendly, post-fossil age that the world is preparing for. Even the Arab Emirates are decarbonizing.

- Some industries and sectors represent a particularly large lever: For example, buildings are responsible for almost 40% of global CO2 emissions along their entire value chain, from construction to use. Steel production is responsible for around 7% of emissions worldwide, in Austria it is 16% due to the large steel producer voestalpine. If we want to achieve the climate targets, we need to make targeted use of precisely these levers.

- How are the two sectors connected? The construction sector needs a lot of steel, but the way it is processed means that it is not always so easy to separate the material. However, green steel production urgently needs this steel scrap – which is also becoming a location issue due to the short supply on the global market.

- The transition to a circular economy is a great opportunity for companies: The future steel scrap market will generate a turnover of 1 billion US dollars in Austria alone and require up to 2,000 new employees.

Ensuring security of supply

The production of more climate-friendly steel is highly dependent on the utilization of scrap potential, as ASCII Director Peter Klimek explains: “It depends on how much scrap is available on the market and whether the necessary infrastructure for transport is in place.” Countries such as Austria with large steel production (voestalpine) are particularly affected by this: This is because, in line with the EU climate targets, 80-95% of CO2 emissions are to be cut across the EU by 2050.

Steel scrap thus becomes a strategic resource. “This means that security of supply can be problematic. We need to understand this strategically,” pleads the scientist. This is because the switch to electric arc furnaces is taking place across Europe, and they all need scrap steel to operate. Access to this resource will determine whether steel production in these countries remains sustainable. Klimek: “There simply won’t be enough scrap steel to support steel production with recycling alone. The better the access to scrap, the sooner we will succeed in decarbonizing.”

The quality of the waste is also closely linked to this: “It needs a certain degree of purity. For this reason, it is important to know where this scrap comes from, in what quality was it used and subsequently compressed? You have to look at this level of detail.” One example: If a car is pressed together, this scrap steel is contaminated with copper from the cables. In order to be able to process the scrap further, the composition must be analyzed during production – and in what purity were the materials used?

Recycling in the construction sector: long-term conversion

Simply removing the steel and collecting the waste is not enough to get the circular economy going and exploit this potential. The global and European scrap trade needs to be radically restructured. According to Klimek, the individual sectors also need to plan for recycling as early as the production and development stages: “In reality, you have to think about the cycle at every stage of the product life cycle.”

For the construction industry, this means that the circular economy needs to be considered right from the planning stage, i.e. how important raw materials and resources can be recovered. Currently, the materials are permanently installed and soldered – so they are largely contaminated and difficult to separate. Additionally, buildings are built for long-term use, and the life cycle of steel in these structures can be up to 100 years. Steel that was used many decades ago is being removed here.

The other challenge: China – the world’s largest steel producer – is already one step ahead: In recent years, their scrap trade has largely decoupled from the global market. “At the same time, many countries in Europe are currently relying on scrap exports and are therefore running the risk of parting with a valuable raw material for their own industry,” explains Klimek. These supply chains will (have to) change in order to retain access to this valuable material.

“A new branch of industry is emerging”

The good news is that the new arc technology is promoting a new branch of industry. “We need a new company ecosystem that works hand in hand with the new technology and closes the loop,” explains Peter Klimek. This creates a new market and new growth opportunities for companies.

This future ecosystem will be analyzed in more detail in the coming years. In a joint project between the ASCII, the Complexity Science Hub and voestalpine, the market dynamics, scrap availability and possible logistical challenges are to be investigated.

Klimek: “We estimate that we will need 30 new companies with up to 2,000 additional employees for these tasks in Austria. This will create a market with a total turnover of around 1 billion US dollars – in Austria alone. That would be double the current status. As this changeover is happening throughout Europe, companies can also shine throughout Europe if they act quickly.”

The preliminary study “Circular transformation of the European steel industry renders scrap metal a strategic resource” by P. Klimek, M. Hess, M. Gerschberger, S. Thurner is available for download here.

Author: Anja Herberth

Chefredakteurin